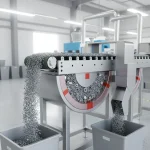

In industrial purification processes, sometimes the power of standard permanent magnets may be insufficient. When it is necessary to capture very fine ferromagnetic particles and weak magnetic contaminants, electromagnetic filter technology steps in. The controllable magnetic field created by electric current is the greatest feature that distinguishes these filters from mechanical solutions. The fact that the magnetic field disappears when the current is cut also makes the cleaning process incredibly easy.

An electromagnetic filter is generally preferred in demanding fluids such as ceramic slurry, glass raw materials, or high-viscosity chemical liquids. Unlike standard magnets, the power of these systems can be adjusted according to need. This flexibility provides full control against varying contamination rates in different production batches. New generation designs focused on energy efficiency keep operating costs at a minimum while providing maximum separation performance.

If you want to move the quality standards in your production line to the next level, investing in an electromagnetic filter is one of the most profitable moves in the long run. With their sensitive coil structure and stainless steel housing, they are manufactured to withstand the toughest industrial environments. To zero out customer complaints and quality control returns caused by metal leaks, this technological solution will become the heart of your facility.

The operational advantage of an electromagnetic filter lies in its ability to handle high-flow volumes without compromising on capture efficiency. As the liquid passes through the energized matrix, even the most minute iron oxides are bonded to the filter elements. This ensures that the final product meets the most stringent purity requirements of modern industry.

Furthermore, the maintenance of these units is remarkably streamlined compared to traditional methods. Once the power is switched off, the trapped particles are released, allowing for a swift flush of the system. This reduces downtime and ensures that the filter is ready for the next cycle with its full magnetic capacity restored. It is a sophisticated approach for facilities that prioritize technical excellence.

Ultimately, integrating an electromagnetic filter into your workflow signifies a commitment to high-end manufacturing. Whether you are dealing with delicate glazes or industrial chemicals, this system provides the reliability you need. It is an essential component for any business aiming for a flawless production output.