In sectors such as mining, recycling, and quartz processing, purifying the material requires surgical precision. A roll magnetic separator has the ability to sort even very fine-grained and weakly magnetic substances at high speeds. Thanks to its high-intensity roller equipped with neodymium magnets, it catches even the smallest impurities that traditional methods miss, bringing raw material quality to its peak.

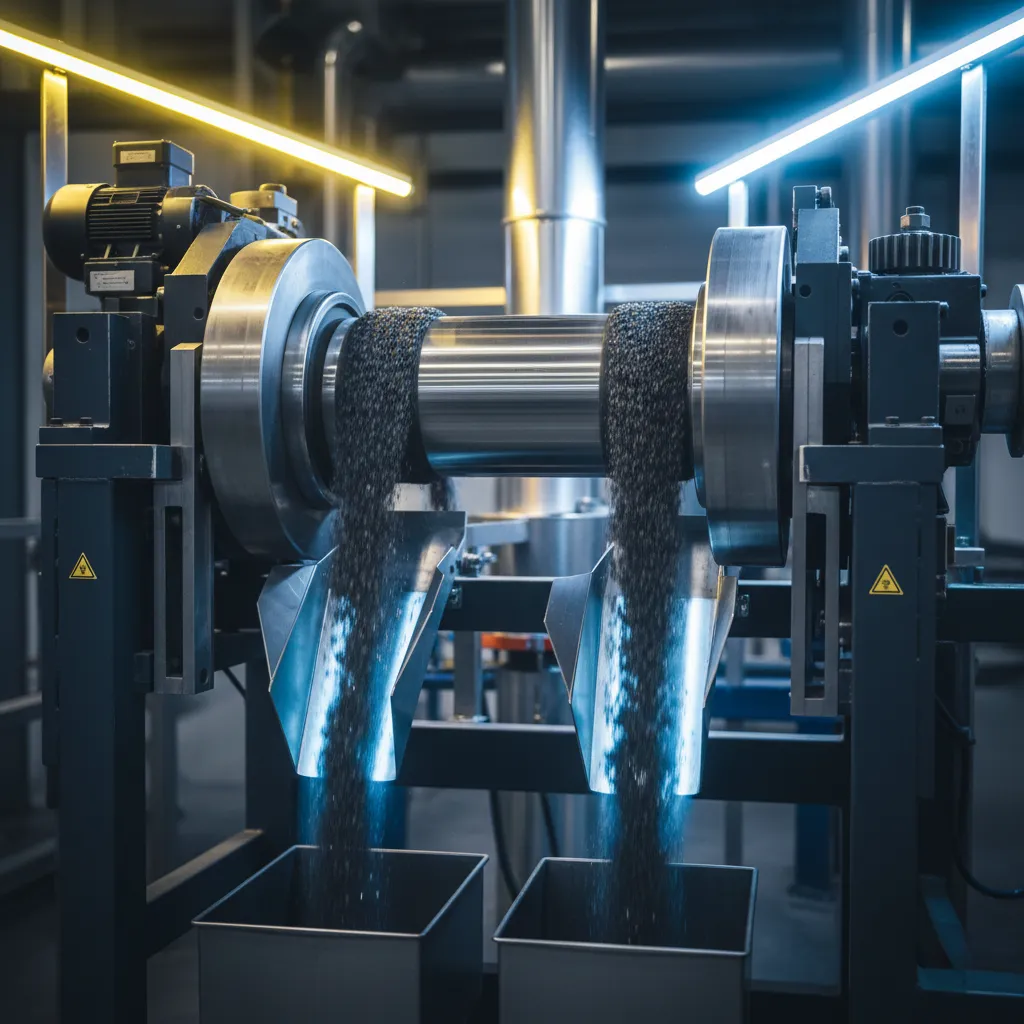

The working principle is quite impressive: the material passing over a thin conveyor belt meets the roll magnetic separator roller with high attraction power. Magnetic parts are held longer by the roller and fall into a separate bin, while the pure material continues on its way. This continuous flow allows the facility to reach the highest purity rate without reducing its tonnage capacity. This system is unrivaled, especially in the cleaning of industrial minerals such as glass sand and feldspar.

There are many roll magnetic separator models with different belt widths and roller diameters available in the market. Choosing the right configuration for your business increases the market value of the final product while reducing waste rates. If paramagnetic (weakly magnetized) substances in the raw material are causing headaches, it is high time to switch to a high-field intensity roll separator solution.

The durability of a roll magnetic separator is a key factor in its long-term value. These machines are engineered to operate in dusty and abrasive environments without losing their magnetic strength. The precise engineering of the magnetic circuit ensures that the flux is concentrated exactly where it is needed most, providing a consistent grade of separation across the entire width of the belt.

Implementing this technology also contributes to a more sustainable production cycle by maximizing the recovery of valuable materials. In the recycling industry, a roll magnetic separator can effectively reclaim small metallic fragments from non-metallic streams, turning waste into profit. It is a versatile tool that adapts to the evolving needs of various material handling applications.

In conclusion, the roll magnetic separator stands as a cornerstone of modern mineral and material processing. By investing in this high-performance equipment, you ensure that your output meets international quality standards. It is the most effective way to handle difficult-to-separate materials with confidence and efficiency.