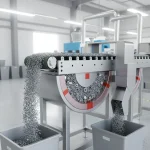

In production lines, especially when dealing with free-flowing powders or granulated raw materials, cleaning metal contamination is not always an easy task. Magnetic drawer separator systems provide the most practical and effective protection by being integrated directly into pipelines or machine inlets. These drawers, usually consisting of stacked magnetic bars, create a maze through which the material passes, capturing even the smallest metal particles. Moreover, they do not slow down the material flow or cause any clogging during this process.

The biggest advantage of using a magnetic drawer separator for a business is its ease of installation and use. These units can be quickly mounted on existing square or round lines, and their nested magnet alignment maximizes the probability of the material contacting the magnetic surface. In many different fields, from the food industry to plastic production, they serve as the final control point just before the packaging stage. This means providing a “zero metal” guarantee for the product going to the final consumer.

The cleaning process explains why these systems are so popular. Thanks to the drawer’s rail system, the magnet group is pulled out, and the metal particles accumulated on the surface are cleaned in seconds, allowing the system to be reactivated immediately. If there is very intense contamination in your line, manual or pneumatic models that allow cleaning without stopping the flow can also be preferred. The fact that the magnetic drawer separator body is made of stainless steel is a critical standard for food safety and longevity.

Quality control standards in modern production facilities are becoming stricter every day. To meet these standards, high-performance separators like the magnetic drawer separator have become a necessity rather than a luxury. A drawer equipped with neodymium magnets successfully holds not only visible bolts and nuts but also micronized iron dust caused by machine wear. This is a factor that directly extends the life of sensitive molds and other expensive machinery downstream.

A magnetic drawer separator selected in the correct capacity and size is the insurance of your business. When the low investment cost is compared with the magnitude of the protection it provides, it is one of the equipment with the fastest return on investment. These systems, which your personnel can easily manage and do not require energy consumption, offer a permanent and professional solution to the metal contamination problem in your factory.

Investing in a well-engineered housing ensures that there are no leaks or pressure drops within your gravity-fed or pneumatic systems. By maintaining a clean flow, you ensure that your brand remains synonymous with quality. This simple yet effective device is the guardian of your product integrity from the warehouse to the shipping dock.