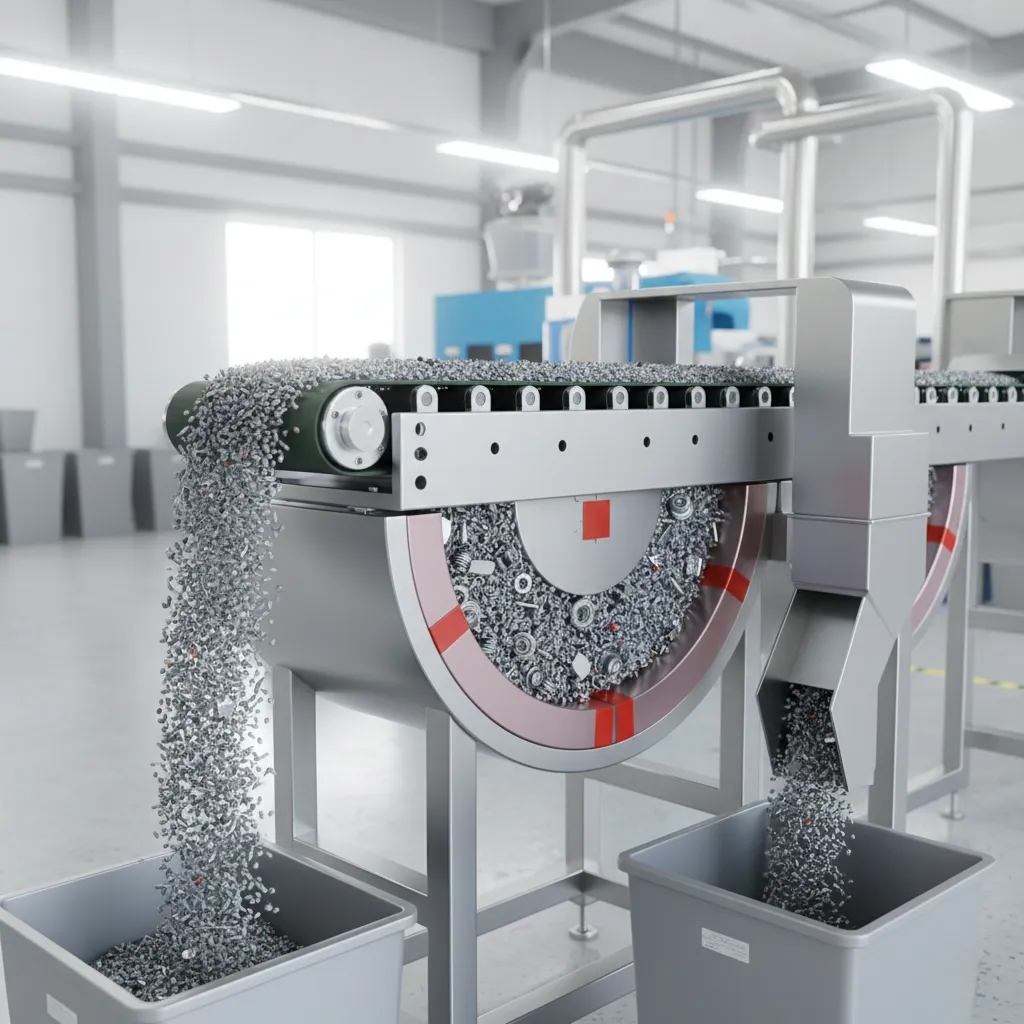

Separating ferromagnetic parts from bulk materials is a process that must be decided and implemented within seconds in mass production. Magnetic drum separator systems step in at this point, classifying the flowing material with high precision. The fixed magnet block inside the drum and the rotating stainless steel shell outside automatically separate metals and divert them in a different direction while allowing the clean material to continue on its way.

The greatest advantage offered by a magnetic drum separator system is that it completely eliminates the need to stop production for cleaning. Since the magnetic field is active only at a certain angle of the drum, the trapped metals fall off spontaneously at the bottom point where the magnetic field ends. This “self-cleaning” structure is an invaluable comfort for modern factories operating 24 hours a day. It reduces operator errors and the burden of manual cleaning to zero.

There is a wide range of applications, from grain cleaning in the food sector to granule separation in plastic recycling. A magnetic drum separator works consistently without loss of performance even in high-tonnage flows. Thanks to its compact and modular design, it can be easily adapted to existing pipelines, elevator outlets, or conveyor ends. Its durable internal mechanism continues its duty without losing magnetic power even under the friction of the harshest and most abrasive materials.

Increasing the raw material purity rate in industrial processes directly increases the quality and market value of the end product. When you extract nuts, bolts, or fine metal shavings using a magnetic drum separator, you both certify your product quality and minimize the risk of failure for sensitive equipment. Especially drums used immediately before expensive crushing and grinding machines are the most loyal protectors of the entire system.

For a correct magnetic drum separator configuration, material moisture, flow rate, and particle size must be carefully analyzed. Special models reinforced with neodymium magnets are strong enough to catch even stainless steel dust showing the weakest magnetic properties. This technology not only separates metal but also becomes the main automation element determining the general efficiency standards of the facility.

If you include automation and long-lasting mechanical solutions in your investment plans, magnetic drum separator systems will be the most reliable business partner of your facility. It provides both labor savings and a separation process free from human error. For metal-free, pure, and high-quality production, you can rely on the continuous performance offered by this technological solution.