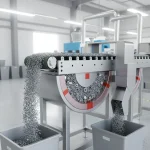

The main challenge during the screening of liquid or powder materials is to remove metal residues without disturbing the fluidity of the material. Magnetic grate systems combine mechanical screening and magnetic separation at a single point, doing what traditional screens cannot. These systems filter out all ferromagnetic contaminants in the flow through high-intensity magnetic grids placed in the passage path. It is the most critical safety point, especially in the production of powder foods such as flour, sugar, and spices.

The performance of a magnetic grate unit depends on the density of the magnet bars within it. The distance between the bars is meticulously designed to be wide enough for the product to pass easily and narrow enough for metal particles not to escape. This delicate balance prevents pressure loss in the production line while increasing separation efficiency to over 99%. This process, which directly affects the quality of the raw material, guarantees product purity at the final stage.

Magnetic grate models used in industrial facilities are manufactured from stainless steel with high corrosion resistance. This allows them to be used safely not only in dry foods but also in acidic or high-temperature liquid lines. The smooth surface of the magnet bars prevents the material from sticking to them while providing great convenience to the operator during cleaning. In areas such as the pharmaceutical industry where hygienic standards are at the highest level, sealing and easy sterilization features make this equipment indispensable.

A hidden benefit of investing in a magnetic grate in businesses is protecting the overall health of the machinery. A grate system located at the beginning of the line prevents subsequent, more expensive, and complex machines (pumps, crushers, filling units) from being damaged by metal leaks. This significantly reduces unexpected failure downtimes and spare parts costs. These units, which act as a continuous shield, are the silent workers that pull down the total production cost.

In conclusion, using a high-quality magnetic grate is the most solid step you can take to protect your brand image and consumer health. This technology, which minimizes the risks of metal contamination in the production process, saves you from potential product recall operations and legal liabilities. These separators, which you can use safely at every point of your factory, are the clearest indicator of modern and clean production.

By choosing a custom-sized grid, you can ensure that even the most difficult-to-handle materials are thoroughly scrubbed of iron. Whether you are dealing with vertical drops or hopper inlets, the static power of a magnetic grate ensures nothing harmful passes through. It is a one-time investment that provides a lifetime of security for your processing plant.