If you are looking for the most rapid and economical solution to metal contamination in production lines, the answer is definitely the magnetic rod. These devices, which usually consist of high-strength magnets placed inside a stainless steel tube, can be integrated anywhere with a “plug-and-play” logic. Whether you place them in a discharge outlet or at a hopper inlet, they instantly trap unwanted metals on their surface from the flowing material.

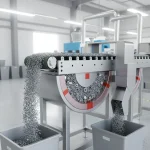

Magnetic rod designs provide great flexibility for businesses thanks to their modular structure. While they can be used as a single unit, they can also be combined to create custom grate systems. They show high success not only in powder or granular products but also in liquid lines. Cleaning is extremely practical; you can reactivate the system in seconds by simply wiping away the accumulated metal waste from the smooth surface.

A high-quality magnetic rod should have a 316L stainless steel body sealed with argon welding for leak-proofing and corrosion resistance. This guarantees product safety, especially in sectors with high hygiene sensitivity like food and pharmaceuticals. These low-cost but vital pieces of equipment pay for themselves very quickly by protecting your large and expensive machines from damage caused by metal impact.

The versatility of the magnetic rod makes it an essential tool for maintenance teams. Because they require no power source to operate, they provide consistent protection even during power outages. Their static nature means there are no moving parts to wear out, making them one of the most durable components in a factory’s filtration arsenal. They are the first line of defense against tramp iron in any processing environment.

In many cases, a simple magnetic rod can prevent a total system shutdown. By catching a stray bolt or a shard of metal early in the process, it ensures that the rest of the machinery continues to run smoothly. This simplicity is its greatest strength, allowing for easy inspection and immediate verification of the contamination levels within the production flow.

In conclusion, implementing a magnetic rod strategy is a smart move for any facility manager focused on quality control. They offer a scalable solution that grows with your production needs. From simple hand-held checks to complex multi-tier arrays, these rods ensure that your raw materials are free from harmful metallic impurities, maintaining the integrity of your final product.