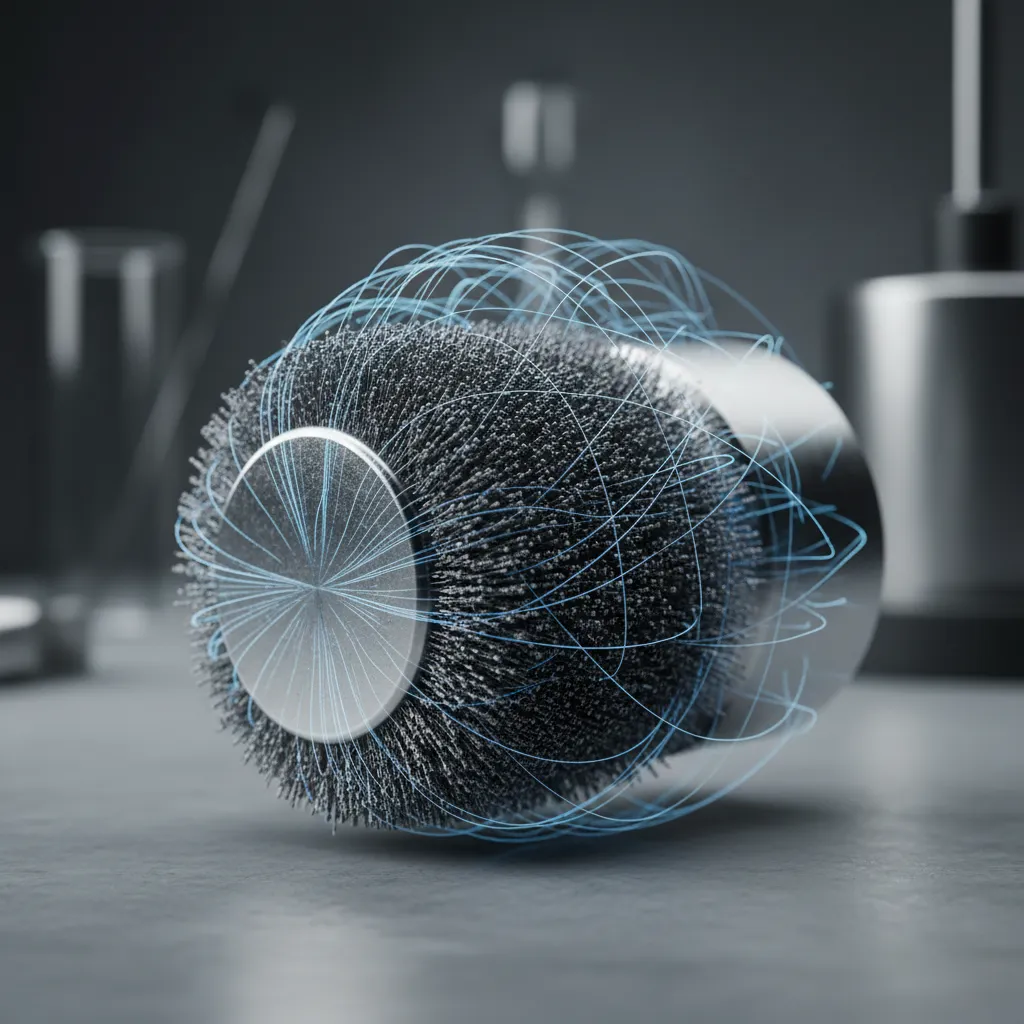

When traditional ferrite magnets fall short, neodymium magnet solutions, the world’s strongest permanent magnets, come into play. Manufactured from rare earth elements, these special components have the capacity to pull hundreds of times their own weight. Despite their small size, the massive magnetic force they exhibit makes them an indispensable part of industrial sorting systems. This superior attraction power is essential, especially for capturing micron-sized metal dust.

A neodymium magnet stands out not only for its pull force but also for its long-lasting performance. When a model with the correct coating and temperature tolerance is selected, it can operate for years without losing its magnetic properties. From food facilities to the defense industry, the high Gauss values provided by these magnets are trusted to ensure product safety. The intensity of the magnetic field traps even the most elusive metals within fast-flowing materials in seconds.

However, using a neodymium magnet requires expertise, as such high power can lead to cleaning difficulties if the design is incorrect. For this reason, they are usually integrated within stainless steel sleeves or utilized through specialized mechanisms. If you want to meet global quality standards like HACCP or BRC in your business, you must include high-grade neodymium components in your systems to guarantee flawless results.

Beyond their strength, these magnets offer a compact solution for modern engineering challenges. Their high energy density allows for smaller machinery designs without sacrificing performance. In an era where space efficiency is as important as power, neodymium magnet technology provides the perfect balance. They are the primary choice for high-speed separation lines where every millisecond of contact counts.

Investing in high-quality magnetic materials reduces the risk of equipment damage downstream. By removing even the smallest fragments, a neodymium magnet protects expensive rollers, blades, and sensors from catastrophic failure. This preventative approach saves businesses thousands of dollars in potential repair costs and lost production time. It is a small component that makes a massive difference in operational reliability.

Ultimately, the choice of a neodymium magnet reflects a commitment to using the best technology available for material purity. Whether you are upgrading an old line or designing a new facility, these magnets provide the peak performance required by today’s industrial standards. They are truly the “superpower” of modern manufacturing, ensuring that your output remains pure and your brand stays protected.