In modern factories, time is the biggest cost. Stopping production for manual cleaning means a loss of labor and energy. Self cleaning magnetic separator systems are designed specifically to close this efficiency gap. These systems provide 24/7 protection by automatically discharging the metals they trap while the raw material flow continues, without requiring human intervention.

In heavy industrial sectors where there is intense metal pollution, manual cleaning can be both laborious and dangerous. However, a self cleaning magnetic separator initiates the cleaning cycle periodically via sensors or timers. This ensures that the attraction power of the separator always remains at its peak level. Since metal saturation does not occur, the risk of stray metal parts falling back into the product is reduced to almost zero.

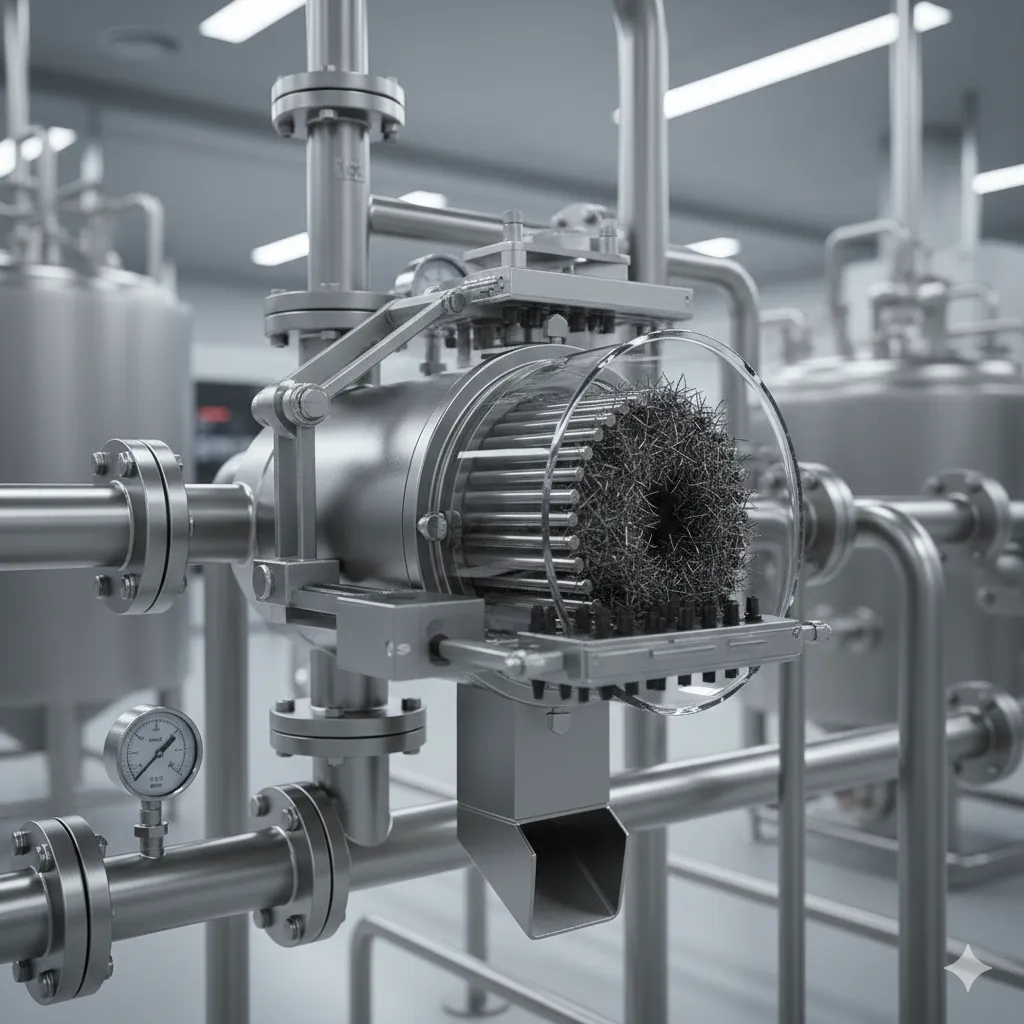

How do these systems work? Usually operating with a pneumatic mechanism, the self cleaning magnetic separator separates the collected ferromagnetic waste from the raw material path and empties it into a special waste bin. This process does not cause even the slightest slowdown on the production line. In sectors like food and pharmaceuticals, where “zero error” is mandatory, this technology is the most critical link in quality control.

When you include a self cleaning magnetic separator in your business, you are not just buying a device; you are investing in automation comfort. Personnel errors are prevented, occupational safety is increased, and most importantly, your production capacity remains uninterrupted. In the world of Industry 4.0, getting rid of manual processes will significantly increase your competitive strength.

Beyond efficiency, these systems offer unparalleled reliability in high-volume environments. They are built to withstand harsh conditions while maintaining precision. By automating the extraction of tramp iron, you ensure that your downstream equipment—like grinders and crushers—remains protected from catastrophic damage.

Ultimately, transitioning to an automated separation process reflects a commitment to excellence. A self cleaning magnetic separator is a silent partner in your facility, working tirelessly to maintain the purity of your output. It is the smart choice for any operation looking to scale without compromising on quality or safety.